3000-5000nm AR Coated Sapphire Infrared Windows

3000-5000nm AR Coated Sapphire Infrared Windows is designed to maximize transmission and minimize reflectance in 3-5μm. Coligh manufactures different substrate infrared windows

- Premium sapphire material

- Anti-reflective coating

- Wide Spectrum High Transmission Coverage 3000-5000nm

Products Categories

Get A Free Quote

3000-5000nm AR Coating on Sapphire Windows for Infrared Optics Description

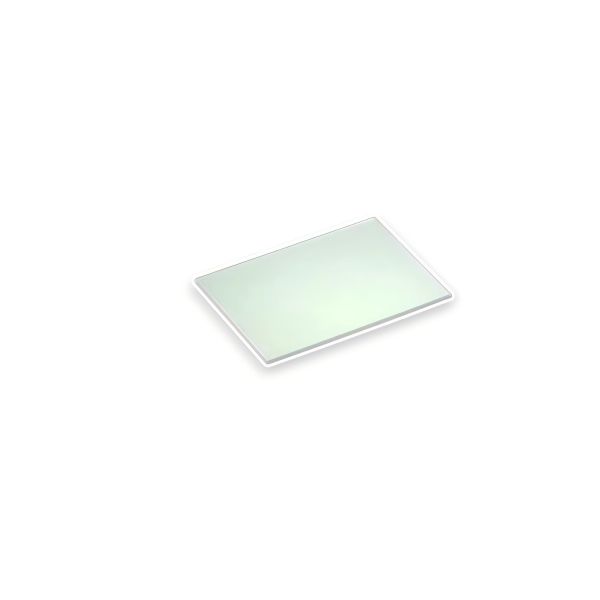

3000-5000nm AR (anti-reflective) coated sapphire infrared window is a high-performance infrared optical window designed for mid- and far-infrared bands.

- This infrared optical window produced by Coligh is made of high-purity sapphire crystal combined with advanced coating technology.

- It has the characteristics of ultra-wide infrared transmission range, and the mid- and far-infrared transmittance of 3000-5000nm is greater than or equal to 90% or 95%, which is especially suitable for applications such as CO/CO₂ laser (3-5μm), thermal radiation detection and gas analysis.

- As an optical base, sapphire has the advantages of scratch resistance and wear resistance, and is suitable for long-term use in dust and vibration environments.

- Through the ion beam deposition process, the multi-layer film system is optimized for the 3-5μm band, and the AR coating significantly improves the transmittance,

3000-5000nm AR Coated Sapphire Infrared Windows Technical Datasheet

| Parameter | Specification |

| Substrate Material | Sapphire |

| Wavelength Range | 3000 nm – 5000 nm |

| Coating Type | Anti-Reflective (AR) |

| Average Transmittance | ≥ 90% or >=95% (within 3000-5000 nm range) |

| Surface Quality | 60-40, 40-20 |

| Coating Method | Ion-assisted deposition / Electron-beam evaporation |

| Custom Options | Available upon request (wavelength tuning, dual-side) |

3000-5000nm AR Coated Sapphire Infrared Windows Applications

- Thermal imaging system

Thermal imaging needs to operate for a long time in harsh environments such as high temperature, high humidity, and dust. Traditional infrared windows are susceptible to thermal deformation or corrosion, resulting in blurred imaging and system failure. Sapphire windows protect internal sensors from environmental damage with their ultra-high hardness and thermal stability; AR coatings improve the transmittance in the 3-5μm band to ensure efficient capture of thermal radiation signals. - CO₂ laser processing

CO₂ laser wavelengths have harmonic energy in the 3-5μm band. Traditional ZnSe windows are prone to beam distortion due to thermal lens effects and are easily oxidized by high temperatures. Sapphire’s high temperature resistance prevents thermal damage; customized AR coatings accurately match laser wavelengths to reduce reflection losses - Military defense

When missiles fly at high speeds, windows need to withstand extreme aerodynamic heating, rain erosion, and electromagnetic interference, and ordinary materials are prone to cracking or signal attenuation. Sapphire’s thermal shock resistance ensures structural integrity; wide-band high transmittance ensures distortion-free transmission of infrared guidance signals. - Gas leak detection

Gases such as methane and carbon monoxide have characteristic absorption peaks in the 3-5μm band, and high-transmittance windows are required to ensure detection sensitivity. AR coating is optimized for 4.2-4.5μm, with a transmittance of >99%. Combined with the corrosion resistance of sapphire, it is suitable for the acidic gas environment in chemical sites.

Get Free Quote Of Custom 3000-5000nm AR Sapphire Windows for Infrared Systems

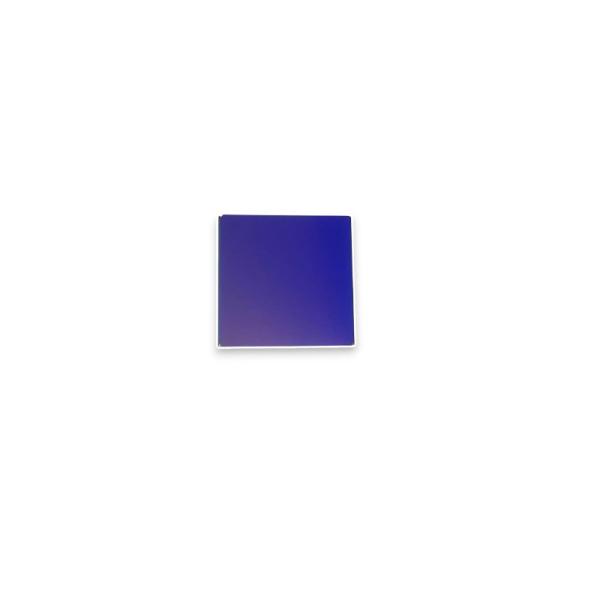

Related Products

Related News

Introduction: What Is Full-Band Infrared? “Full-band infrared” typically refers to infrared technologies capable of detecting and imaging across the key […]