1200-5500nm AR Coated Silicon Infrared Window

1200-5500nm ar coated silicon infrared window is optical window optimize for 1200-5500nm range. Coligh is the manufacturer of infrared optical windows.

- Wide wavelength range 1200-5500nm transmission

- High performance Silicon substrate

- Advanced Anti-reflective coating

Products Categories

Get A Free Quote

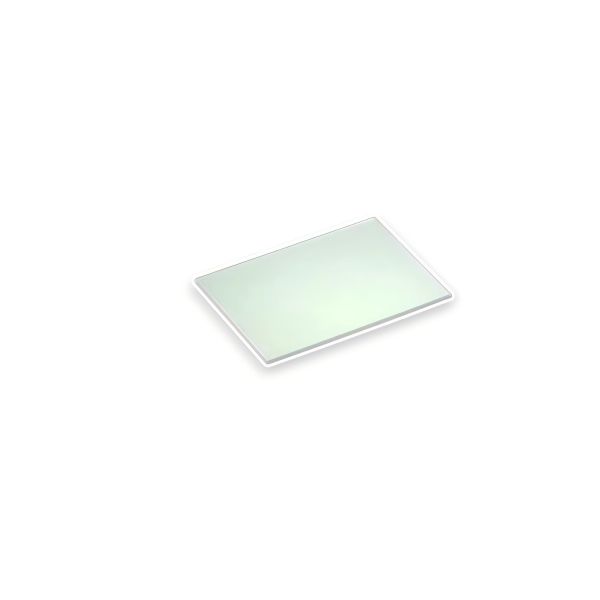

Broadband AR Coating on Silicon Window for 1200-5500nm Infrared Description

1200-5500nm AR Coated Silicon Infrared Windows Coligh manufactures are designed for high-performance infrared optical systems

- It covers broad wavelength range. It is Optimized for transmission in the 1200-5500nm infrared spectrum (MWIR and LWIR)

- We applied AR coating on the silicon windows. The tranmsission of 1200-5500nm is above 85%, it reduce the reflection losses.

- We use silicon susbtrate to coat the windows. Silicon is highly durable, with excellent thermal conductivity

- We support any custom on size, coating, shape or other special requirement

1200-5500nm AR Coated Silicon Infrared Window Technical Datasheet

| Parameter | Specification |

| Substrate Material | Silicon |

| Wavelength Range | 1200-5500nm (SWIR-MWIR-FIR) |

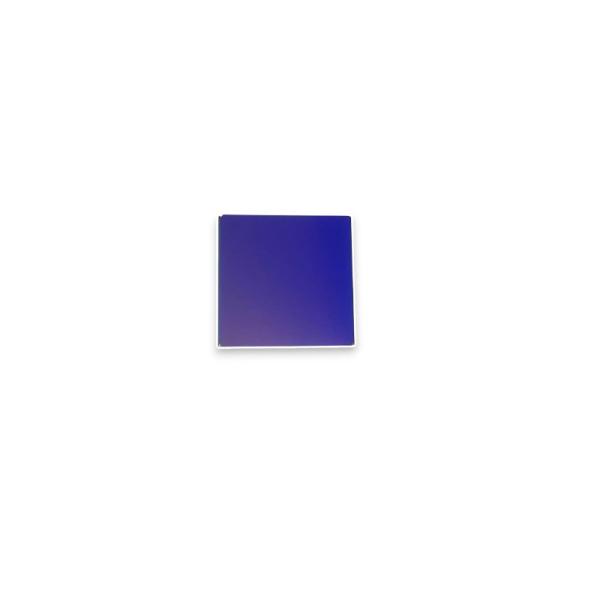

| Coating Type | Anti-Reflective (AR) |

| Average Transmittance | ≥ 85% (within 1200-5500nm range) |

| Surface Quality | 60-40, 40-20 |

| Coating Method | Ion-assisted deposition / Electron-beam evaporation |

| Custom Options | Available upon request (wavelength tuning, dual-side) |

1200-5500nm AR Coated Silicon Infrared Window Applications

- Infrared thermal imaging

Silicon has high transmittance in the infrared band (1.2-5.5μm), but its surface reflectivity is high, about 30%, which will cause light energy loss and image contrast reduction. AR coating can significantly reduce reflection and improve imaging quality. This infrared optical window is installed as an optical window at the front end of the infrared detector or lens to protect the internal sensor from environmental damage while allowing infrared light to pass efficiently. - High-power laser

CO₂ laser and mid-infrared laser will lose energy and generate return light when reflected on the surface of the silicon window, which may damage the laser. AR coating can suppress reflection and ensure efficient transmission of laser. It can also be used as a protective window in the laser cavity or transmission path to block pollutants such as dust and water vapor, while ensuring that the laser beam passes through with low loss. Thereby reducing energy loss and improving the efficiency of laser processing - FTIR, Raman spectrometer

Spectral analysis requires high-precision light signal acquisition. The reflection loss of the silicon window will cause spectral signal attenuation and affect the detection sensitivity. 1200-5500nm AR Coated Silicon Infrared Window can be installed on the sample chamber window or the front end of the detector for transmission or reflection spectral measurement. AR coating can maximize infrared light transmittance and improve signal-to-noise ratio. - Aerospace

Spacecraft or missile seekers need to work in extreme environments. The high mechanical strength and heat resistance of silicon materials can protect sensors, while AR coating ensures efficient transmission of infrared signals. This optical window can be used as a protective window for missile fairings and satellite infrared cameras to resist aerodynamic heating and particle impact.

Get Free Quote Of Custom 1200-5500nm AR Coated Silicon Infrared Windows for Sensors

Related Products

Related News

Introduction: What Is Full-Band Infrared? “Full-band infrared” typically refers to infrared technologies capable of detecting and imaging across the key […]