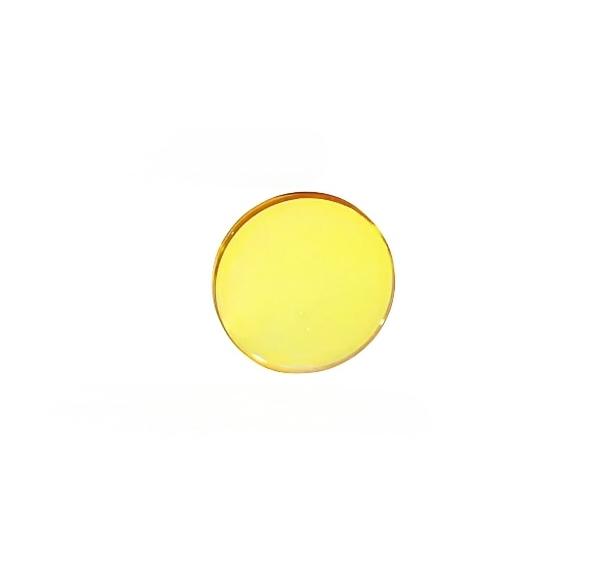

Zinc Sulfide Windows

FAQs

A ZnS window is an optical window made of zinc sulfide (ZnS), primarily used in the infrared range (3–12 μm), with high transmission especially in the long-wave infrared (LWIR) region of 8–12 μm.

We support customization of ZnS windows:

-

Size and shape: Any shape, with diameters up to 1000 mm

-

Surface accuracy: Customizable up to 0.25″ surface flatness

-

Coatings: AR (anti-reflection), HR (high-reflective), or other coatings tailored to specific IR bands or laser wavelengths

AR-coated ZnS windows significantly improve transmission at specific wavelengths by reducing surface reflection losses. They are mainly used in infrared thermal imaging, laser optical systems, and spectroscopic analysis.

ZnS windows transmit in the 0.4–12 μm range and offer higher mechanical strength with a Mohs hardness of 3.5. They are suitable for medium to low-power applications and harsh environments.

ZnSe windows have a broader transmission range from 0.5–20 μm and a lower Mohs hardness of 2.5. They are better suited for high-power CO₂ lasers and broadband infrared systems.

We offer single-band AR coatings, broadband AR coatings, high-reflective coatings, DLC coatings, and laser-damage-resistant coatings for ZnS windows.

-

Military and security: IR windows for missile seekers, tank thermal imagers, and UAV IR sensors

-

Industrial inspection: High-temperature monitoring (e.g., furnace observation), infrared inspection of electrical equipment

-

Medical and scientific: IR microscopes, laser surgical instruments, and gas analysis spectrometers

-

Aerospace: Satellite IR remote sensing systems and aircraft FLIR windows

-

Consumer devices: Vehicle night vision systems and smart home infrared sensing modules