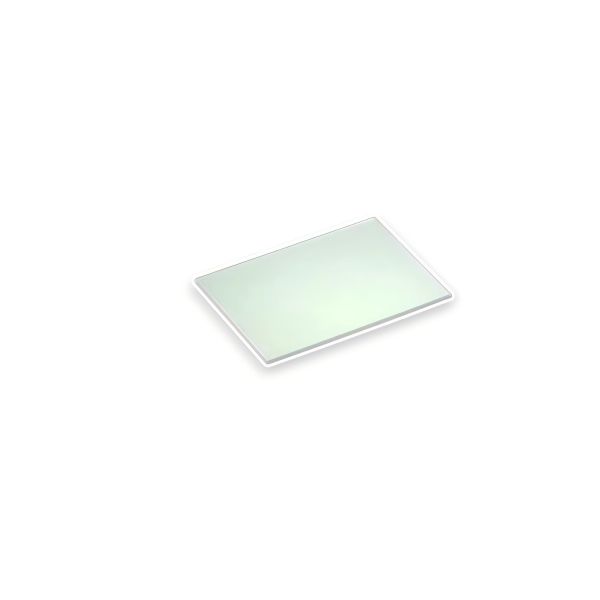

8000-14000nm FIR Antireflection Coatings Silicon Windows

8000-14000nm FIR Antireflection Coatings Silicon Windows is optimized for Far-infrared high transmission and low reflectance. Coligh manufactures various IR windows

Products Categories

Get A Free Quote

8000-14000nm FIR Antireflection Coating Silicon Optical Windows Description

8000-14000nm Far Infrared Anti-Reflection Coated Silicon Window Coligh manufactures is designed for the 8-14μm far infrared band, with a multi-layer wide-band anti-reflection film on the surface. We significantly reduce the surface reflectivity of the far infrared band by optimizing the optical matching of silicon-based materials and multi-layer film systems, covering the entire 8-14μm band. The transmittance is increased to more than 80%.

- This silicon window has high transmittance in an ultra-wide band. In the 8-14μm far infrared band, the transmittance is >=80%, supporting weak thermal radiation signal detection

- We use ion beam assisted deposition coating process to coat the anti-reflection film to ensure high density and strong adhesion of the coating, and withstand extreme temperatures and mechanical shocks.

- Silicon has extreme environmental tolerance and performs well in resisting environmental erosion and mechanical damage.

- We support window processing with diameters from 1mm to 1000mm, and can customize flat, spherical, aspherical or special-shaped structures.

8000-14000nm FIR Antireflection Coatings Silicon Windows Technical Datasheet

| Parameter | Specification |

| Substrate Material | Silicon |

| Wavelength Range | 8000-14000nm |

| Coating Type | Anti-Reflective (AR) |

| Average Transmittance | ≥ 80% (within 8000-14000nm range) |

| Surface Quality | 60-40, 40-20 |

| Coating Method | Ion-assisted deposition / Electron-beam evaporation |

| Custom Options | Available upon request (wavelength tuning, dual-side,size up to 10000mm, any shape to be customized) |

8000-14000nm FIR Antireflection Coatings Silicon Windows Applications

- Industrial manufacturing

The internal temperature of steelmaking furnaces and glass melting furnaces is as high as 1000°C or above, and far-infrared thermal imaging is required to monitor the melting state in real time. However, traditional quartz windows are easy to soften at high temperatures, and the far-infrared transmittance is insufficient. 8000-14000nm silicon windows can be made into furnace observation ports as optical transmission and thermal barriers: they can be directly exposed to the high temperature environment in the furnace and work for a long time without deformation; and they can clearly capture the flow and temperature distribution of molten metal. - Infrared stealth drone optical window

When drones perform reconnaissance missions at night, the engine thermal radiation (8-14μm) is easily detected by the enemy’s infrared system, and the window material needs to have both high transmittance and low self-radiation characteristics. This silicon window can be used as a protective window for the infrared camera and seeker of drones, and the special coating suppresses the thermal signal of the 8-14μm band itself - Far-infrared spectral analysis of atmospheric pollutants

Greenhouse gases in industrial waste gas have characteristic absorption peaks in the 8-14μm band, which require a far-infrared spectrometer for accurate detection, but traditional germanium windows have low transmittance in long-wave infrared and are easily affected by humidity, resulting in data drift. This silicon window can be integrated into the detection end of an open optical path spectrometer, covering the CO₂ and CH₄ absorption peaks to improve detection sensitivity; - Fire rescue thermal imager window

In the high temperature and dense smoke environment at the fire scene, firefighters need to use thermal imagers to locate trapped people, but ordinary windows are easily damaged by high temperature radiation or polluted by smoke, resulting in blurred imaging. This infrared precious window can be used as a front protective window for firefighting thermal imagers, which can withstand +800°C flame impact for a short time and protect internal optical devices;