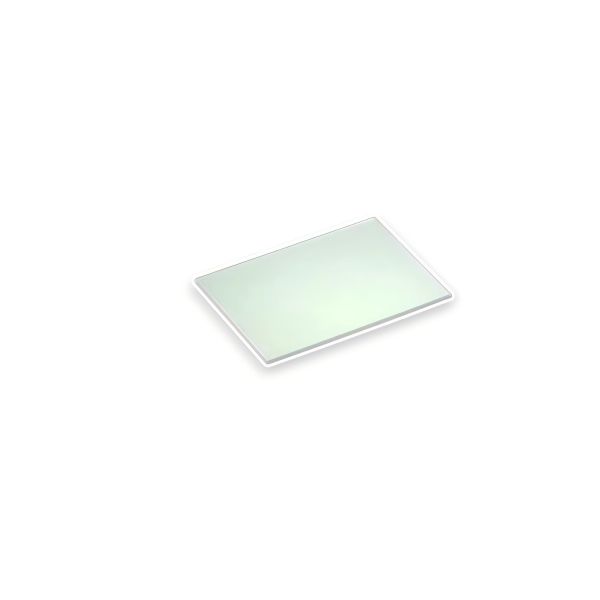

3500-5000nm Infrared Antireflection Coating Silicom Windows

3500-5000nm Infrared Antireflection Coating Windows is optimized for infrared range transmission. Coligh manufactures various material IR antireflective windows

- Wavelength range is 3500-5000nm high transmission and low reflection

- Broad band AR coating for 3500-5000nm

- Silicon substrate

3500-5000nm Infrared Antireflection Coated Optical Silicon Window Description

3500-5000nm infrared anti-reflection coating window Coligh manufactures is an optical window designed for mid- and long-wave infrared spectra. We use high-performance silicon as the substrate, ion-assisted deposition (IAD) or magnetron sputtering process, and by coating multiple layers of thin film materials with different refractive indices, we can achieve high-efficiency anti-reflection in a wide band of 3500-5000nm to offset the reflected energy of the incident light.

- Silicon material has a natural high transmittance in the 3.5-5μm band, but its high refractive index causes the surface reflectivity to be as high as more than 30%. We achieve ultra-low reflection and high transmittance through multi-layer anti-reflection coating design.

- In the 3500-5000nm band, it has ultra-high infrared transmittance, which can reach more than 95%, significantly enhancing the signal strength of the infrared system.

- With wide-band compatibility, a single mask layer covers the entire 3.5-5μm band

- The silicon substrate itself has unique advantages, such as a hardness of Mohs 7, impact resistance, wear resistance, and is suitable for harsh industrial environments. In addition, the operating temperature range of -200°C to +500°C is suitable for high-temperature furnace monitoring or low-temperature superconducting experiments.

3500-5000nm Infrared Antireflection Coating Silicom Windows Technical Datasheet

| Parameter | Specification |

| Substrate Material | Silicon |

| Wavelength Range | 3500-5000nm |

| Coating Type | Anti-Reflective (AR) |

| Average Transmittance | ≥ 95% (within 3500-5000nm range) |

| Surface Quality | 60-40, 40-20 |

| Coating Method | Ion-assisted deposition / Electron-beam evaporation |

| Custom Options | Available upon request (wavelength tuning, dual-side,size up to 10000mm, any shape to be customized) |

3500-5000nm Infrared Antireflection Coating Silicom Windows Applications

- Laser cutting or welding

When cutting metal or welding precision parts, the laser head needs to work for a long time in an environment with high temperature and splashing metal debris. Ordinary optical windows are prone to laser energy attenuation or even component damage due to reflection loss, thermal damage or surface contamination. Integrating the silicon window at the light outlet of the laser head or in front of the focusing lens as a protective barrier can reduce reflection loss in the 4-5μm band, reduce energy loss, and increase laser power utilization by more than 30%; - Infrared imaging monitoring of natural gas pipeline leakage

Natural gas has strong absorption characteristics in the 3.3-3.5μm band, and infrared imaging technology is required to detect pipeline leaks in real time. Conventional optical windows are easily corroded by environmental humidity and corrosive gases, and reflection loss causes weak signals to be missed. 3500-5000nm Silicom Windows can be embedded in the front end of the infrared thermal imager lens, covering the CH₄ absorption peak 3.3um and background radiation band, capturing weak methane leakage signals and increasing detection accuracy - Mid-infrared biological tissue imaging

The molecular vibration spectrum of lipid and protein characteristic absorption bands in the 3-5um band contains key information for disease diagnosis, but traditional infrared windows (such as KBr) are easy to deliquesce and have low mechanical strength, which cannot meet the needs of in vivo detection. This silicon window can be integrated into mid-infrared optical coherence tomography or microscope systems, with a transmittance of >97% in the 4-5μm band, ensuring the clarity of deep tissue imaging, achieving micron-level resolution imaging of living tissue, and facilitating early cancer screening - Missile infrared seeker window

When the missile is flying at high speed, the seeker window needs to withstand aerodynamic heating, temperature >800°C, dust impact and strong electromagnetic interference, while ensuring high transmittance and anti-interference ability in the 3.5-5μm band. This infrared silicon window can be used as the outermost optical protection layer of the missile’s infrared seeker. Combined with the antistatic coating, it can reduce the interference of electromagnetic pulse (EMP) on the detector.

Get Free Quote Of High Transmission 3500-5000nm IR Silicon Window with Antireflection Coating

Related Products

Related News

Introduction: What Is Full-Band Infrared? “Full-band infrared” typically refers to infrared technologies capable of detecting and imaging across the key […]